| Sign In | Join Free | My disqueenfrance.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My disqueenfrance.com |

|

Brand Name : GIENI

Model Number : GLU-1300

Certification : CE

Place of Origin : Shanghai

MOQ : 1

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Delivery Time : 90

Packaging Details : Film+Polywood Case

Type : FULL AUTOMATIC SILICONE LIPSTICK MOLD MACHINE

Application : Lipstick (Regular, Slim or Mini Type)

Filling Method : Piston Filling, servo driven

Production Capacity : 1000 ~ 1,300 PCS/HOUR

Operator : 2 people (Only 1 people after mount with robot)

Power supply-1 : 3phase 5 wire - 380V/ 50-60HZ/ 3 PHASE & MAX.23KW

Power supply-2 : Air supply - 0.6 MBAR above

Compressor : 5HP

1000PCS/H Silicone Lipstick Filling Machines Piston Type 5HP Compressor

Frame of lipstick filling machine

1, Aluminum base, surface steel material Chrome-plated treatment.

2, SUS plate cover on surface, Stainless steel control cabinet and door.

3,Wheel for machine movement and foot for locking. Material loading station can be removed and carried.

4, Euro standard aluminum profile for protection frame.

5, PE door.

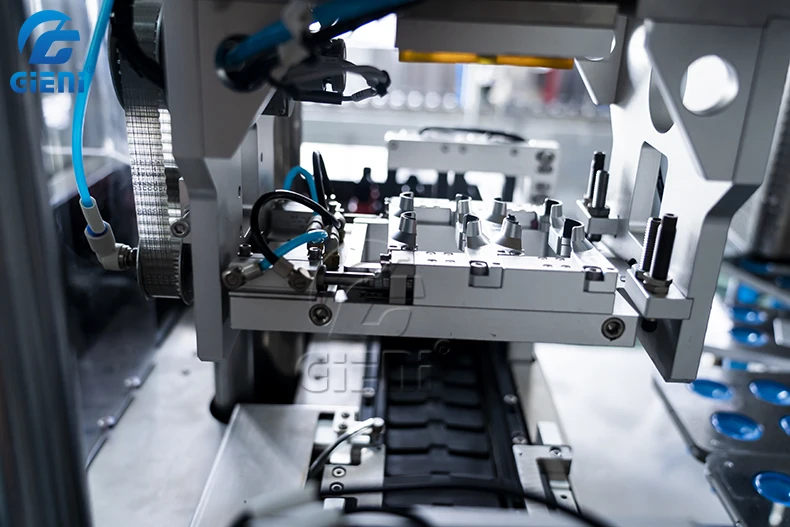

Table Drive System of lipstick filling machine

1, Import technique and the ring rails, plus 28sets silicone rubber holding mold(anodizing process).

2,Station Lift control adopts servo driven module.

3, 112pcs silicone rubber mold with Stainless steel plate cover on.

4,Driving part full sealed, cooling part with dual layer warm-keeping and sealed.

Pre-heating device of lipstick filling machine

1,Composed of 2units LEISTER brand Hot Air Gun, blow rate and heating rate are adjustable.

2,Cylinder control the Hot Air Gun’s Lifting Up/down.

3,Hand wheel adjust the height.

4,Hot Air Blowing time is adjustable.

5,PID display the Temp.(With air fan, speed control)

Filling machine (2units)

1,Moveable Filler(2 Nozzle), dual step motor to individual control each nozzle’s filling volume; 2nd mixing function.

2,20L Tank, outer cleaning system.

3,2nd Nozzle pre-heat, bulk collection function.

4,Tank with oil heating function, precise control the bulk temp.

5,Adopts dual layer pipe to transfer bulk.

6,Servo motor driven gear pump (Italy Technology)

7,Cylinder control niddle valve’s switch

8,AC motor drive the stirrer

9,PLC control Electrical system

10,Control part composed of touch screen and buttons.

Nozzle moving system

1,Air Cylinder control nozzle on/off

2,Air Cylinder control nozzle backward/forward

3,Heating tube heat the nozzle

4,SUS material bulk collect tray

5,Air cylinder control the horizontal moving of material tray.

Re-heat Device

1,Consists of LEISTER(Import from Switzerland)

2, Heater height control by hand wheel

3,Temp.setting on touch screen, fan volume adjust manually.

Cooling Unit

1,Separated water circulation type cooling device.

2,Temperature range max -20℃.

3,6Hp compressore

4,Digital temperature control and display.

5,R404A refrigerant freon gas

6,Cooling tunnel installed underneath table.

7,Adopt pipeline circulate the cold air.

8,Dual layer insulation material outside the cooling tunnel.

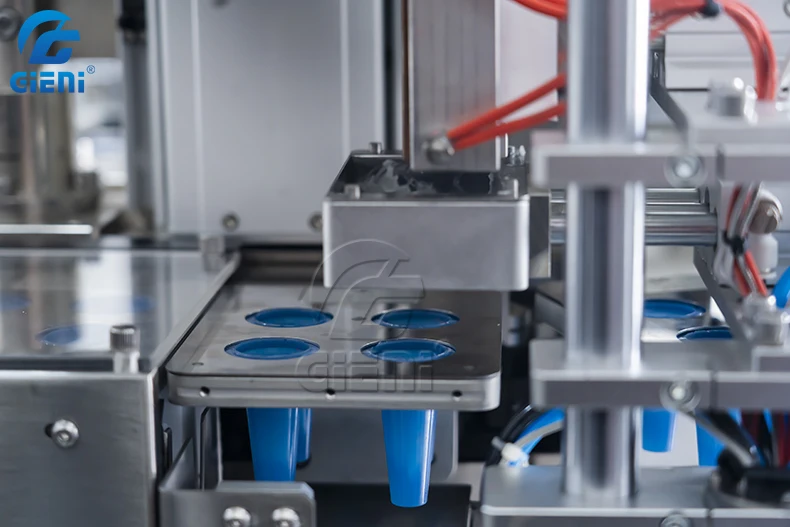

Discharging Unit

1,High Precision Industrial Module control the movement of Y/X direction and lifting up/down.

2,Grasper the container 4pcs.

3,Rotary cylinder control the grasper’s rotating.

4,Air Cylinder control the vacuum system’s lifting up/down.

5,Two-stage vacuum system to release lipstick out of the silicone rubber. Grasper is changeable(Self-patent). No need change vacuum station when the lipstick size within 8mm-17.1mm(diameter). Grasp tense is adjustable.

6,Plastic Material conveyor to transfer molds.

7,TT chain type conveyor to transfer lipstick container mold.

Screw Down Unit

1,Air cylinder control the grasper’s on/off.

2,Can change the silicone rubber on grasper.

3,Servo motor control the grasper’s rotating.

4,Torque control the lipstick rotating and falling down.

5,Releasing could be semi or automatic.

Electronic Control Device

1,Mitsubishi(FX5U) - Made in Japan

2,Weinview Touch Screen 10 inch – Made in Taiwan

3,Mitsubishi Servo Motor – Made in Japan?

4,Ring rail – Italy Tech, Made in China

5,Air tac Cylinder – Made in Taiwan

6,Alberts vacuum generator. –Made in German

7,JSCC motor – Made in Taiwan

8,Fan – Made in Taiwan

9,Temperature module – Made in Korea

|

|

1000PCS/H Silicone Lipstick Filling Machines Piston Type 5HP Compressor Images |